What is Traditional RFID Tracking?

Radio-frequency identification (RFID) uses digitally encoded data embedded in specialized tags or smart labels. Specially designed readers can capture this data and decode it for the user. Similar to barcoding, RFID equipment helps to identify materials by providing data that coincides with information within the user’s database. Unlike barcodes, RFID tags can be detected by proximity and without line-of-sight. This allows users to process data more quickly, accurately and efficiently than barcodes. However, LivePoint® RFID tracking is the greater alternative to both traditional methods, offering a range of flexibility and benefits that are unique to its system.

Benefits of LivePoint® RFID Tracking

LivePoint® RFID tracking offers numerous benefits over outdated barcode and serial number tracking methods. Some of the advantages of using our LivePoint® RFID tracking systems include:

Increased Product Visibility

LivePoint® RFID tracking technology can locate products from anywhere in a facility. This allows users to track inventory through every step of the fulfillment and shipping process. Not only does this make it easier for users to check on the status of particular orders, but it also helps companies prevent issues related to misplaced or lost items, disorganized inventory, oversights, and other human errors that are unavoidable in manually controlled processes.

Enhanced Employee Productivity

Since employees do not have to physically look through or scan multiple items to locate equipment with LivePoint® RFID technology, they may use their time more productively. RFID tags and labels can be located from anywhere within the facility, which allows employees to more quickly and efficiently locate and procure products. Employees no longer need to run back and forth within the facility to locate, identify, and carry items, which greatly increases overall productivity.

Reduced Risk and Loss

LivePoint® RFID tracking technology helps companies mitigate risk and loss by reducing the potential for manual errors and ensuring quick and accurate access to inventory data and location. With immediate access from anywhere in the facility, it becomes easier to account for items at all times, reducing the potential for costly mistakes.

How Does RFID Tracking Work?

How Does RFID Tracking Work?

There are multiple different types of RFID solutions based on what someone is looking to accomplish. For our purposes today, we will strictly be addressing “Passive UHF” technology.

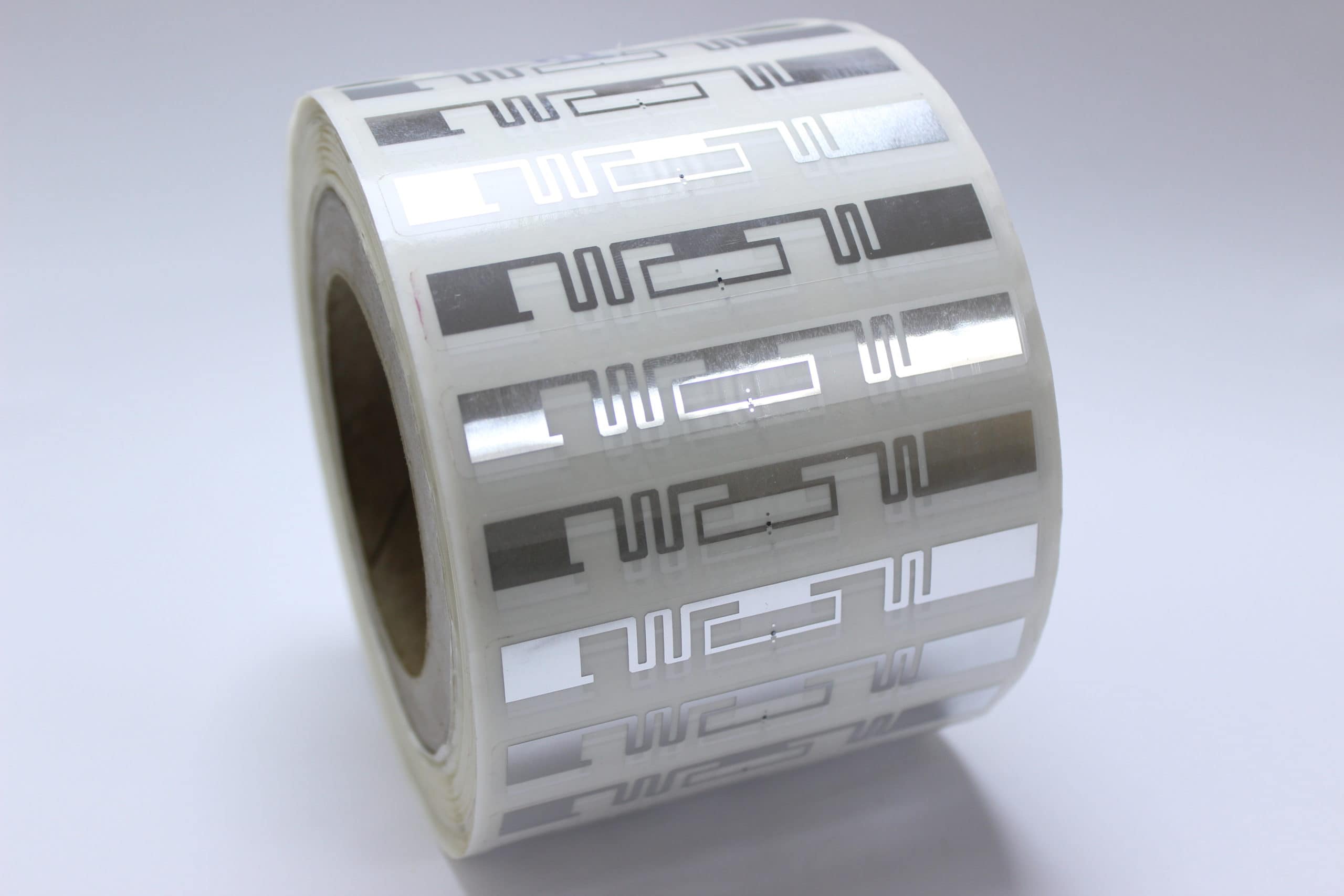

Passive RFID systems require three distinct components: A Passive RFID label or tag, an antenna, and an RFID reader. RFID tags use an internal circuit to store information such as a pallet “license plate” or other identification. The RFID reader sends out a signal through an antenna. When the signal is received by a Passive RFID tag, it energizes the internal circuit of the passive tag and the internal circuit sends back a signal with the information stored in it. These tags are considered consumable/disposable and are very inexpensive. They are used by many companies today including retail, manufacturing and warehousing. The data can then be transferred to the user’s computer system, where it can be stored, analyzed, and/or reconciled.

The Importance of RFID Tracking

With RFID technology, finding, tracking, and keeping an inventory of equipment and assets proves extremely easy and eliminates mistakes. Without RFID, companies must use barcodes, serial numbers, and spreadsheets to track equipment, components, and other items. These processes are prone to delays, mistakes, and missed deadlines due to the sheer amount of manual labor necessary to keep track of all of the company’s assets.

With RFID technology, companies can automate the process of tracking Products/inventory without the errors and high expenditure of time and labor. Without the need for manual scanning and data entry, Products can be inventoried and tracked much more quickly and efficiently, significantly reducing operating costs.

Applications of RFID Tracking

RFID tracking systems are extremely versatile, which makes them useful for a wide range of tasks and applications.

Inventory Management

RFID is critical inventory management for warehouses, distribution centers, retail facilities, and manufacturing centers, among others. With RFID systems, users can receive real-time product information such as location, quantities, and order progress, thereby streamlining inventory processes and reducing labor hours.

Supply Chain Management

RFID tracking helps to streamline supply chain operations by providing easy tracking information that can be transmitted between locations. Shipping and receiving becomes easier to complete with quick RFID checks on inventory as it departs and arrives.

IT Asset Tracking

As mobile technology becomes increasingly incorporated into the workplace, IT departments need to keep track of smaller and more portable assets. Employers can use RFID technology to keep track of company-issued mobile phones, tablets, laptops, and other assets.

Returnable Transit Item Tracking

Returnable transport items such as pallets, totes, trays, and other containers allow manufacturers, warehouses, and distributors to move products in an efficient and sustainable manner. RFID tracking allows distributors to track the location and condition of these items to ensure the secure and dependable transport of goods. In addition, RFID trackers help supply chain workers ensure that items are returned in a timely fashion for reuse.

About LivePoint® RFID from A-1 Packaging Solutions, Inc.

At A-1 Packaging Solutions, Inc., we are dedicated to helping our customers modernize and streamline their warehouse operations through the use of data-driven, real-time inventory management and product tracking. Our state-of-the-art LivePoint® platform features RFID technology that provides a constantly updated flow of information regarding inventory, assets, processes, and shipping status. With timely data, users can make well-informed decisions to improve productivity, profitability, and employee accountability in real time.

A-1 Packaging Solutions, Inc. uses the latest digital technology and cutting-edge tools to take you light-years beyond barcodes and spreadsheets. With LivePoint® products, you obtain a snapshot of every aspect of your company’s operation for optimal visibility and enhanced operational control. We tailor our systems to meet the particular need of your operation by conducting full process mapping of your company. We then implement systems specifically geared toward tracking your company’s product inventory, returnable containers, and employee activity without hands-on management.

Quality Tracking Technology From A-1 Packaging Solutions

For nearly 20 years, A-1 Packaging Solutions has been providing innovative and sustainable packaging solutions for companies. Our goal is to help our customers establish sustainable, cost-effective practices using the latest RFID technology. With A-1’s patent pending LivePoint® products, you can streamline every aspect of your operation, from inventory and cycle counts to employee productivity and training. To learn more about ways that A-1’s LivePoint® RFID systems can improve your processes, contact our experts today!

How Does RFID Tracking Work?

How Does RFID Tracking Work?